Latest news:

Boiler Water Management - Boiler Water Carryover

Boiler Water Management - Chemical Control & Boiler Integrity

Chemical Cleaning - Operating Costs

Chemical Cleaning - Process Plant Management

Boiler Water Management - Oxygen Removal for Boiler Water Treatment

Case Study - Chemical handling, System Upgrades & Common-up

Convergent Cooling Systems - pH relay upgrades

Associations:

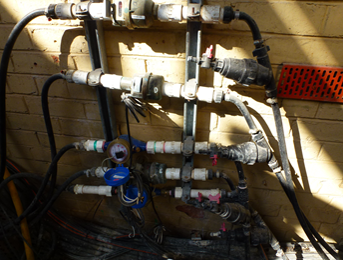

Chemical handling, System Upgrades & Common-up

Purpose of this case study

To demonstrate CORE’s capabilities to improve site efficiencies and safety onsite by reducing chemical handling and improving robustness of onsite systems

DISADVANTAGE OF NOT COMMONING-UP

Six control systems = high probability of control / pump / probe issues each service visit

Very high level of operator / consultant time required fixing control issues, topping up small chemical drums and individually testing all towers

Individual Brominators = weekly top ups required = high chance of spills and very high level of chemical / manual handling component

20l chemical drums = weekly change over = very high chemical / manual handling component

Plastic spill pallet bunding = below specification for segregation of chemicals

No corrosion monitoring

Poor HCC & LP control

ADVANTAGES of COMMONING-UP SYSTEM:

Single controller with internet monitoring using a single set of probes / pumps = email / sms notification to consultants and operators of any out of spec parameters or low level chemical tanks

Bulk chemical supply = Chemical transfer frequency ever 4 – 6 months = minimal chemical / manual handling of chemicals

Portable bunding = segregation of acids and alkalines with sufficient spill space

Excellent HCC & LP control

Excellent corrosion monitoring and control

OLD Situation:

Individual make-up and bleed water meters for all six towers = many not operational and not recorded

Six individually controlled cooling systems

NEW Situation:

Single make-up water meter and single bleed water meter for all six towers running off a common balance tank and recirculation pump

ADVANTAGES:

Water usages trended weekly

Body of water continually circulating = greater biological and corrosion control

One body of water = one lot of testing - This has significantly reduced required testing from six systems to one system allowing more time to be spent identifying other projects and improving other systems onsite

Summary

Individual Systems

Six control systems = high probability of control / pump / probe issues each service visit

Very high level of operator / consultant time required fixing control issues, topping up small chemical drums and individually testing all towers

Individual Brominators = weekly top ups required = high chance of spills and very high level of chemical / manual handling component

20l chemical drums = weekly change over = very high chemical / manual handling component

Plastic spill pallet bunding = below specification for segregation of chemicals

No Corrosion monitoring

HCC within spec 80% - LP within spec 83% 2013

System Common - Up

Upgrade to single controller system with internet monitoring

Single make-up water meter and single bleed water meter for all six towers running off a common balance tank and recirculation pump – Water usage monitored weekly

Bulk chemical supply = Bulk Transfer every 8 – 10 weeks

Portable bunding = Segregation of acids and alkalines with sufficient spill space

Corrosion rates 2013 – 2015 Average 1.45mpy (Target <3.0mpy)

HCC & LP control 100% within spec 2014 & 2015