Associations:

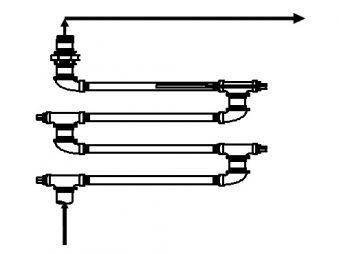

Closed Loop Systems

- are typically found in production plants &comfort cooling operations

- are generally built into structures and the level of access is limited

- have high repair costs due to their location and potential for disruption of services

- risk extensive damage due to failure of piping if not maintained

- operate with a low water loss (<10%annum on system volume)

The Objectives of the Treatment Program

- to support sound mechanical design

- to inhibit corrosion on the various metals that arepresent

- to prevent deposition of hardness salts and corrosion products

- In the case of existing systems they should help to move deposits to allow the inhibitors to reach the system metal

Typically a sound treatment program has four functions -

- Ferrous alloy inhibitors designed to protect mild steel

- Yellow metal inhibitors designed to protect copper and alloys

- Buffering Agents to control system pH

- Dispersants to disperse solids

Well managed systems operate for very long periods without issue, if water losses occur & are unnoticed, severe corrosion & fouling can occur.

Cleaning can be achieved online by -

- Relying on corrected treatment to slowly remove corrosion or scale and capture them by filtration of the circuit

- On-line cleaning with surfactant/polymerto remove organic deposits and capture them by filtration of the circuit

- On-line cleaning using elevated levels of phosphonate & polymer to remove corrosion product

Contact us today to find out more!