Associations:

Employee and customer safety is our number one goal in any chemical cleaning exercise & we know that all injuries are preventable.

We continually train all Supervisors & Technicians to ensure a safe work environment each and every job will.

Recently AU$3.2M was saved in lost production at an Australian oil Refinery by effectively cleaning a Diesel rundown HE on line. All procedures, risk management tasks & equipment mobilisation were effected quickly by CORE once the option to online clean had been selected.

The clean was carried out safely, quickly and in an effective manner with:

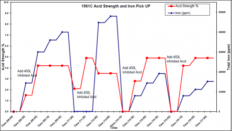

- Four (4) acid shots, clean and flush steps required in a twelve (12) hour period because iron pick up was very rapid saturating the cleaning solution.

- Mild Steel Coupons showed acceptably low metal loss over the duration of the clean

- Temperature recovery across the HE water side was 15C avoiding the need for a complete unit shutdown.

- All waste was neutralised and then carefully disposed of onsite over a period of two (2) weeks with no impact on the environment.

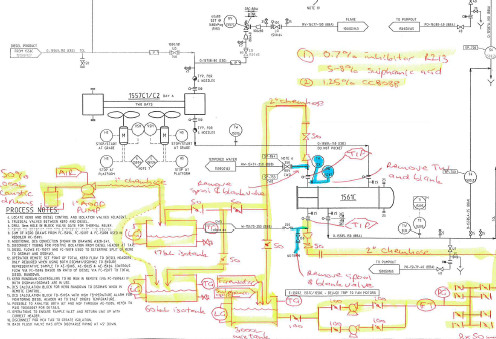

All managed cleaning process’s begin with a plan –

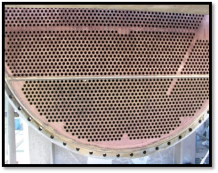

Large multi pass HE can be effectively cleaned on or off line. BEFORE off cleaning appearance & after water blasting to remove as much deposit as possible.

Large multi pass HE can be effectively cleaned on or off line. BEFORE off cleaning appearance & after water blasting to remove as much deposit as possible.Contact us today to find out more!